Technology has transformed the Longview Packhouse in Hawkes Bay. The family-owned and operated business is using state-of-the-art tech to improve consistency, delivering their customers’ perfect boxes of apples.

Stepping inside the tech-laden Longview Packhouse is a step into the future of apple packing.

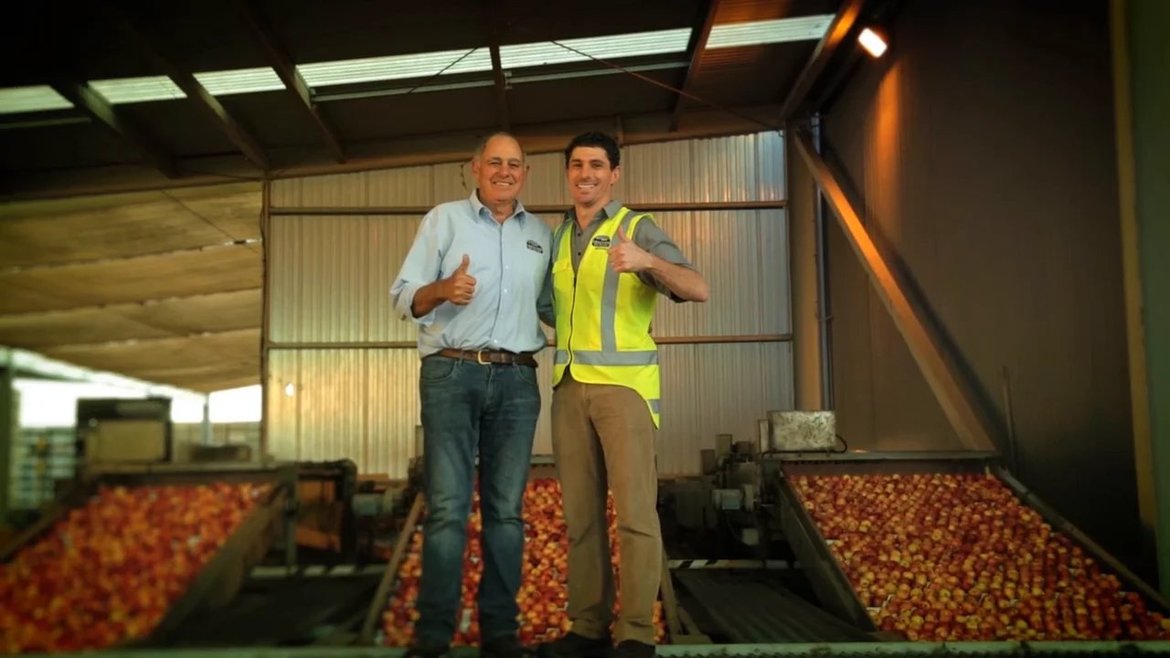

Manager Michael Caccioppoli has embraced state-of-the-art technology so he can deliver apples with the best possible consistency.

The family-owned packhouse which was started by his father Frank four decades ago, is a phoenix that has risen from the ashes after being gutted by fire 10 years ago.

Michael says the fire proved a blessing in disguise, allowing the small family-owned company to invest in the latest technology to improve the packhouse’s outputs.

“We had three key components of technology installed during the rebuild which dramatically increased our ability to deliver the best apples possible to our customers.”

The first of these was a Compac blemish sorter, a huge machine that scans up to 60 apples a second, taking 40 photos of every piece of fruit and sorting them based on their colour, size, shape, and any defects.

The Kiwi-developed Compac sorter technology is widely regarded as the best in the world. The Auckland-based company was founded in 1984 and now supplies more than 30 countries worldwide.

“It’s really changed our business. Dad and myself in my younger days were having to check what our 30 human sorters were letting past and packing, and what they were throwing out. It’s not easy work; they had to make a snapshot decision on each piece of fruit because every piece is subtly different.

“We know we’re now far more consistent and it’s really stabilised the quality of each box. We now pack four grades of fruit and we know every piece of fruit meets the grading target. This has ultimately led to a better return and the ability to make more money out of every piece of fruit.”

A palletising robot was the second piece of tech installed in the packhouse. The long armed robot is able to lift the 18-kilogram boxes of fruit and stack them eight layers high with pinpoint accuracy.

“Once a pallet is completed it’s 2.4 metres high so trying to get humans to stack these is pretty difficult. The boxes are heavy and we used to use rugby players who were able to handle the load. But once we started packing six days a week and outside the hours when these sportsmen were available, we really struggled to meet our targets.

“Because they’re the end of the production line we had to go as fast or as slow as they wanted. Now the end of the line runs as fast as we want it to run and it can run six days a week, 10 hours a day without rest.”

Once the perfect pallets are stacked, they need to be strapped together, leading to the third piece of technology at Longview.

An automatic strapping machine puts corner boards onto the pallet before strapping each pallet eight times - twice as many straps as was possible with manpower.

The conveyor belt machine produces perfectly square pallets that can be easily stacked into a shipping container for transport to Asia, North America, or the UK or Europe.

“Demands from our customers are getting higher, which is fine because we’re asking for more money as we’re producing a more premium product. That means we have to deliver a more consistent product and the technology we use definitely gives us that. Every pallet is the same square and stacked.”

Michael says the investment in technology has solved a labour shortage problem as well as future proofed their business.

“Before we mechanised the packhouse we struggled to find enough labour to meet demand. We’ve embraced tech and we see it as a necessary part of our business so we can continue to keep up with the requirements of our customers for many years to come.”